The 4L60E is a versatile GM automatic transmission known for its durability and reliability. Widely used in Chevrolet Silverado and similar vehicles, it offers smooth performance. Its electronic design enhances efficiency, making it ideal for daily driving and performance modifications.

Overview of the 4L60E Transmission

The 4L60E is a GM-designed automatic transmission known for its reliability and versatility. Commonly used in Chevrolet Silverado and similar vehicles, it offers smooth shifting and durability. As an evolution of the THM 700-R4, it incorporates electronic controls for improved performance. With its 4-speed overdrive design, it balances efficiency and power delivery. The 4L60E is favored for both daily driving and performance upgrades. Its widespread use has led to extensive documentation, including detailed diagrams and repair manuals, making it accessible for maintenance and modification. A free 186-page rebuild guide is available, covering all aspects of its internals and procedures.

Torque Converter in the 4L60E

The torque converter is a hydraulic coupling that transfers rotational power from the engine to the transmission. It ensures smooth power delivery and efficient operation.

Function and Importance of the Torque Converter

The torque converter is a critical component in the 4L60E transmission, acting as a hydraulic coupling that transfers rotational power from the engine to the transmission. It plays a vital role in smooth acceleration and efficient power delivery. The converter consists of a pump, turbine, and stator, working together to multiply torque during acceleration and allowing the engine to idle without engaging the transmission. Its hydraulic operation ensures seamless communication between the engine and gearbox, improving fuel efficiency and performance. Proper function of the torque converter is essential for maintaining the transmission’s overall reliability and operational efficiency.

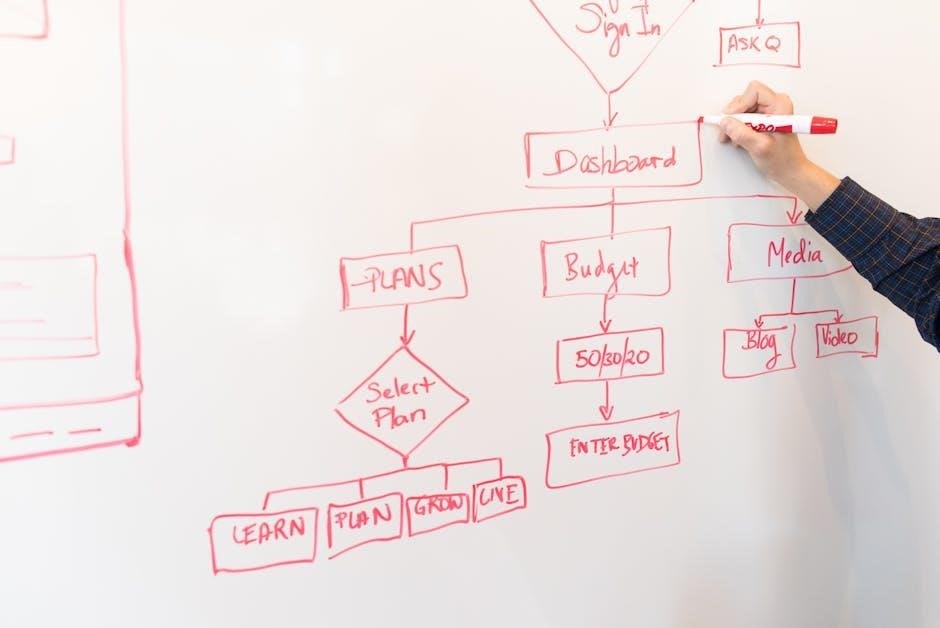

The valve body diagram illustrates the 4L60E’s hydraulic control system, showing solenoids, springs, and valves that regulate fluid flow for smooth gear shifts.

Valve Body Diagram of the 4L60E

Understanding the Valve Body Components

The valve body is the brain of the 4L60E transmission, controlling fluid pressure for smooth gear shifts. It houses solenoids, springs, and valves that direct hydraulic fluid. The diagram reveals the layout of these components, showing how they interact to regulate clutch packs and bands. Solenoids are controlled by the TCM, activating electronic shifts. Springs provide tension to keep valves in their default positions, while fluid channels ensure proper pressure distribution. Understanding this setup is crucial for diagnosing issues and performing repairs, as the valve body’s efficiency directly impacts transmission performance and longevity.

Exploded View Diagram of the 4L60E

The exploded view diagram provides a detailed visualization of the 4L60E’s internal components, showcasing how parts like gears, bearings, and clutch packs are assembled. This layout aids in understanding the transmission’s structure for repairs or upgrades, offering a clear blueprint of its intricate design and functionality.

Visualizing Internal Components

An exploded view diagram of the 4L60E transmission provides a comprehensive visual breakdown of its internal components. This detailed illustration showcases the transmission’s intricate structure, including gears, bearings, clutch packs, and planetary assemblies. By examining the diagram, technicians and enthusiasts can identify individual parts, understand their relationships, and gain insights into the transmission’s assembly. This visualization is invaluable for diagnosing issues, planning rebuilds, and ensuring proper reassembly. The exploded view also highlights the complexity of the 4L60E’s design, emphasizing the precision required for maintenance and repairs.

Identifying the 4L60E Transmission

The 4L60E can be identified by its alphanumeric ID code on a plate near the bellhousing. It also features a 13-bolt pan and specific electrical connectors.

Methods for Proper Identification

To identify a 4L60E transmission, locate the identification plate near the bellhousing. This plate displays an alphanumeric code specific to the model. Additionally, the transmission features a distinct 13-bolt pan and electronic connectors, distinguishing it from similar models. Referencing a detailed diagram or technician guide can provide further clarity, ensuring accurate identification for repairs or upgrades. Proper identification is crucial for selecting the correct parts and procedures, avoiding potential compatibility issues during maintenance or rebuilds.

Common Problems and Troubleshooting

The 4L60E often experiences issues like slipping gears, solenoid malfunctions, and torque converter failure. Diagnosing these problems involves checking fluid levels, wiring, and solenoid operation. Replacing faulty solenoids or adjusting the torque converter can resolve many issues. Regular maintenance, such as fluid changes, helps prevent these problems. Consulting a detailed transmission diagram or repair manual is essential for accurate troubleshooting and repairs, ensuring optimal performance and longevity of the transmission.

Diagnosing and Addressing Issues

Diagnosing 4L60E transmission problems often begins with identifying symptoms like slipping gears or delayed engagement. Checking the transmission fluid level and condition is a first step. Electrical issues, such as faulty solenoids or wiring, can be diagnosed using a multimeter and scan tools to read error codes. Mechanical problems, like worn clutch packs or a failed torque converter, may require disassembly. Referencing a detailed 4L60E transmission diagram can help pinpoint components needing repair. Addressing issues promptly is crucial to prevent further damage. Regular maintenance, such as fluid changes, can help avoid common problems. Always consult a repair manual for precise troubleshooting and repair procedures to ensure long-term reliability.

Rebuild Process and Procedures

A detailed 186-page 4L60E transmission rebuild manual provides comprehensive instructions for disassembling, inspecting, and reassembling the unit. This guide covers everything from tool selection to final testing.

A Step-by-Step Guide

A detailed 4L60E rebuild manual offers a comprehensive guide for transmission rebuilding. It starts with disassembly, followed by component inspection and replacement. The manual emphasizes proper tool usage and alignment. Reassembly involves precise torque specifications and fluid filling. Detailed diagrams ensure clarity, while troubleshooting tips address common issues. This resource is essential for both novices and experienced technicians, providing a structured approach to restoring transmission performance effectively.

Wiring System and Electrical Connections

The 4L60E wiring system connects solenoids, TSS, and safety switches. Proper connector keying ensures accurate transmission operation. A detailed electrical diagram simplifies troubleshooting and installation processes.

Understanding the Electrical Setup

The 4L60E’s electrical system is crucial for its operation. It involves solenoids, sensors, and connectors that control shifting and torque converter engagement. The wiring harness connects these components, ensuring proper communication. A detailed wiring diagram is essential for troubleshooting issues like faulty solenoids or incorrect connector placements. The system also includes a Transmission Control Module (TCM) that processes data from sensors to optimize performance. Proper electrical connections are vital for smooth operation, making the diagram a key tool for diagnostics and repairs. Regular maintenance of the wiring system prevents common issues like erratic shifting or loss of control.

The 4L60E transmission requires specific parts for optimal performance. Key components include the torque converter, valve body, gear sets, and bearings. Regular replacement of worn parts ensures reliability and prevents costly repairs. Always use OEM or high-quality aftermarket parts for longevity. Consulting a detailed parts list or diagram is crucial for accurate replacements and maintenance.

Parts List and Replacement Guide

Essential Components for Maintenance

The 4L60E transmission requires specific parts for optimal performance. Key components include the torque converter, valve body, gear sets, and bearings. Regular replacement of worn parts ensures reliability and prevents costly repairs. Always use OEM or high-quality aftermarket parts for longevity. Consulting a detailed parts list or diagram is crucial for accurate replacements and maintenance. Additionally, components like seals, gaskets, and filter kits should be replaced during servicing to maintain fluid integrity and prevent leaks. Proper tools and torque specifications are essential for a successful rebuild or repair.

The 4L60E transmission is a reliable and versatile unit, ideal for both enthusiasts and technicians. Its durability and performance make it a preferred choice for many vehicles. Utilizing resources like diagrams and manuals ensures proper maintenance and repairs, balancing performance and reliability for years to come.

Final Thoughts and Recommendations

The 4L60E transmission is a reliable and versatile unit, widely used in GM vehicles. Its durability and performance make it a preferred choice for both enthusiasts and professionals. For those working on this transmission, accessing detailed diagrams and repair manuals is essential for proper maintenance and upgrades. Regular checks of the torque converter, valve body, and electrical connections ensure optimal performance. Whether you’re a novice or an experienced technician, understanding the 4L60E transmission’s internals and functions is key to troubleshooting and enhancing its capabilities. Always refer to trusted resources for accurate guidance and safe repairs.