The Kubota instruction manual is a comprehensive guide providing essential information for safe and efficient operation, maintenance, and troubleshooting of Kubota equipment, ensuring optimal performance and longevity.

Overview of Kubota Manuals

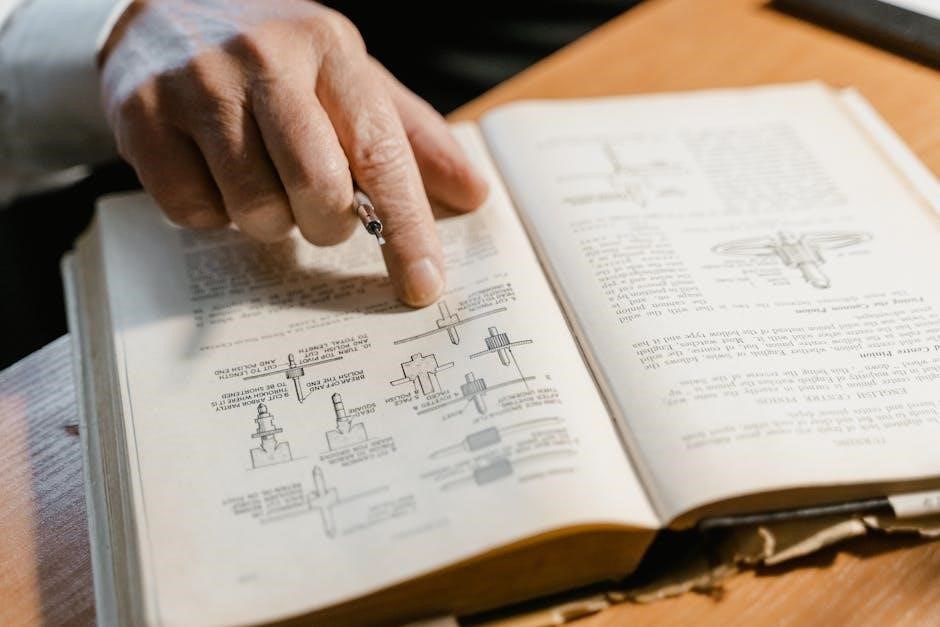

Kubota manuals are detailed guides designed to assist users in operating, maintaining, and repairing Kubota equipment. They include operator manuals, service manuals, and parts diagrams, ensuring comprehensive coverage. These manuals are available in both physical and digital formats, with many downloadable from official Kubota websites or third-party libraries. They provide specifications, installation instructions, and troubleshooting tips, catering to both novice and experienced users. The manuals are regularly updated to reflect the latest advancements in Kubota technology. Digital tools, such as the myKubota app, further enhance accessibility, allowing users to download and reference manuals instantly. Whether for tractors, engines, or construction equipment, Kubota manuals are indispensable resources for optimal performance and longevity.

Importance of Following the Manual

Following the Kubota instruction manual is crucial for ensuring safety, efficiency, and equipment longevity. By adhering to the guidelines, users can prevent accidents, reduce wear and tear, and maintain optimal performance. The manual provides specific instructions for operation, maintenance, and troubleshooting, helping users avoid costly repairs. Proper adherence also ensures compliance with manufacturer recommendations, preserving warranty validity. Regularly reviewing the manual keeps users informed about best practices and updates. This proactive approach not only enhances productivity but also extends the lifespan of Kubota equipment, making it a vital resource for all operators and owners seeking reliable and durable machinery performance.

Types of Kubota Manuals

Kubota manuals include operator, service, and parts diagrams, offering comprehensive guidance for operation, maintenance, and parts identification, ensuring efficient and safe equipment use.

Operator Manuals

Kubota operator manuals are designed to provide clear instructions for the safe and efficient operation of Kubota equipment. These manuals cover essential aspects such as startup procedures, control functions, and daily maintenance checks. They are tailored to specific models, ensuring users can familiarize themselves with their particular machine’s features. Operator manuals also include safety precautions, warranty information, and troubleshooting tips, helping users address minor issues promptly. Available in digital formats, these manuals can be downloaded from official Kubota websites or third-party libraries, making them easily accessible. Regularly reviewing the operator manual ensures optimal performance and longevity of the equipment, while also promoting operator confidence and compliance with manufacturer guidelines.

Service Manuals

Kubota service manuals are detailed technical guides designed for mechanics and professionals to perform advanced repairs and maintenance. These manuals provide in-depth instructions for diagnosing and resolving complex issues, including engine overhauls and hydraulic system repairs. They typically include wiring diagrams, torque specifications, and detailed parts lists. Service manuals are available for various Kubota models, such as the D950 and V1903 engines, and can be downloaded from official Kubota websites or third-party libraries. These resources are essential for ensuring proper repairs and maintaining equipment performance. They complement operator manuals by offering a deeper understanding of the machine’s internal systems, enabling precise troubleshooting and efficient servicing. Regular use of service manuals helps extend the lifespan of Kubota equipment.

Parts Diagrams and Catalogs

Kubota parts diagrams and catalogs provide detailed visual representations of equipment components, enabling users to identify and order specific parts. These resources are crucial for maintenance and repairs. Available as downloadable PDFs, they include exploded views of machinery, part numbers, and descriptions; Users can find diagrams for models like the Kubota B1-15 Bulltra or L2501. Official Kubota websites and third-party libraries offer these resources. They are essential for accurately identifying and procuring replacement parts. Parts catalogs often accompany service manuals, ensuring users can reference both textual and visual guides. This dual approach streamlines repairs and maintenance, preventing errors and saving time. Regularly updated catalogs reflect the latest parts information, ensuring compatibility and accuracy for Kubota equipment owners. They are indispensable for DIY enthusiasts and professionals alike, promoting efficient and effective servicing. Proper use of these diagrams enhances equipment longevity and performance.

Downloading the Kubota Manual

Kubota manuals are conveniently downloadable from official websites and third-party libraries, offering quick access to operator, service, and parts diagrams for various Kubota models, ensuring easy maintenance and operation.

Official Kubota Websites

Official Kubota websites provide direct access to authentic manuals, ensuring accuracy and reliability. These platforms offer operator, service, and parts manuals for various Kubota models. Users can easily search by product type or serial number to find specific documents. The official sites are regularly updated, guaranteeing the latest information and compliance with safety standards. Additionally, they feature user-friendly interfaces, making it simple to download manuals in formats like PDF for easy reference. Accessing manuals through official channels is the recommended method to ensure authenticity and avoid potential risks associated with third-party sources.

Third-Party Libraries

Third-party libraries offer a wide range of Kubota manuals, including operator, service, and parts diagrams. These platforms often provide free access to manuals for various Kubota models, making them a convenient option for users. Websites like ManualsLib and Scribd host extensive collections of Kubota documentation, searchable by model number or equipment type. While these libraries can be helpful, users should exercise caution, as some manuals may be outdated or unofficial. It’s essential to verify the source and cross-reference information with official Kubota resources to ensure accuracy. Additionally, downloading from trusted third-party sites can help avoid potential risks associated with unverified content.

Steps to Download

To download a Kubota instruction manual, visit the official Kubota website or authorized third-party platforms. Navigate to the “Support” or “Resources” section, where you’ll find a dedicated manuals portal. Select your specific Kubota model or equipment type from the dropdown menu. Choose the desired document type, such as an operator or service manual. Follow the prompts to download the PDF file. Ensure you have a PDF reader installed to view the document. Some sites may require account creation or model verification for access. Always verify the manual’s relevance to your equipment and check for the latest updates to ensure accuracy and safety.

Tips for Finding Specific Manuals

When searching for specific Kubota manuals, start by identifying your equipment’s model number, often found on the product or in purchase documents. Use this number to narrow down results on Kubota’s official website or third-party libraries. Utilize search filters for manual type (e.g., operator or service) and language preferences. Additionally, refer to forums or communities where Kubota owners share and discuss manual availability. For rare or discontinued models, contact Kubota customer support directly for assistance. Always ensure the source is reputable to avoid downloading incorrect or outdated information. Regularly check for updates to keep your manual current and relevant. This approach ensures quick access to the exact guidance needed for your Kubota equipment.

Key Sections of the Kubota Manual

The Kubota manual includes essential sections like the table of contents, operating instructions, maintenance schedules, troubleshooting guides, and parts identification to ensure proper usage and maintenance.

Table of Contents

The table of contents in a Kubota manual serves as a roadmap, organizing information logically. It typically includes sections like safety precautions, operating instructions, maintenance schedules, troubleshooting guides, and parts identification. This structure allows users to quickly locate specific information, ensuring efficient navigation. For instance, operators can easily find details on routine maintenance or diagnostic procedures. The table of contents is designed to be user-friendly, making it easier for both novice and experienced users to access the information they need. By following the organized layout, users can maximize the manual’s utility, ensuring safe and effective equipment operation.

Operating Instructions

The operating instructions section of the Kubota manual provides detailed, step-by-step guidance for safely and effectively operating the equipment. It covers pre-operation checks, startup procedures, and proper usage of controls. Clear diagrams and illustrations are often included to help users understand complex processes. Additionally, this section outlines safety precautions and best practices to minimize risks and ensure optimal performance. Instructions are tailored to specific models, addressing unique features and operational requirements. Whether for a tractor, engine, or other machinery, the operating instructions empower users to master their equipment’s functionality. Regularly reviewing this section helps operators maintain proficiency and adapt to any updates or new features.

Maintenance Schedules

The maintenance schedules section in the Kubota manual provides a detailed timeline for routine servicing and inspections. It outlines essential tasks such as oil changes, filter replacements, and lubrication points to ensure equipment longevity. Users can find specific intervals for daily, weekly, and seasonal checks, tailored to their machine’s model and usage. This section emphasizes the importance of timely maintenance to prevent breakdowns and maintain optimal performance. By following these schedules, operators can extend the lifespan of their equipment and ensure reliability. The manual also offers customizable maintenance plans based on operating conditions and hours of use, making it a vital resource for proactive equipment care.

Troubleshooting Guide

The troubleshooting guide in the Kubota manual is designed to help users identify and resolve common issues with their equipment. It provides detailed diagnostic steps for problems such as engine performance, hydraulic malfunctions, and electrical system failures. This section offers practical solutions and repair guidance, enabling operators to address issues quickly and effectively. By following the guide, users can minimize downtime and ensure their equipment runs smoothly. The manual also includes visual aids and charts to simplify the troubleshooting process. Regularly referencing this guide can help prevent minor issues from escalating into major repairs, ensuring optimal performance and equipment longevity.

Parts Identification

The parts identification section of the Kubota manual provides detailed diagrams and descriptions to help users locate and identify specific components of their equipment. This section is crucial for maintenance, repairs, and ordering replacement parts. It includes exploded views of machinery, part numbers, and descriptions, ensuring clarity and precision. Users can quickly reference this guide to understand the structure of their equipment and identify components accurately. The parts identification section is designed to be user-friendly, with clear labeling and organized layouts. It is an essential resource for anyone performing DIY repairs or routine maintenance, helping to ensure that the correct parts are used for optimal performance and longevity of the equipment.

Tools and Equipment for Kubota Operators

Kubota operators require specific tools and equipment for maintenance, repairs, and operation. Essential tools include wrenches, screwdrivers, and diagnostic software, while specialized equipment may involve hydraulic testers and lift kits. Digital tools like the myKubota app enhance functionality and troubleshooting. These resources ensure efficient and safe operation of Kubota machinery, catering to both routine and complex tasks. Proper tools and equipment are vital for maintaining performance and extending equipment lifespan. Operators should always refer to the manual for recommended tools and equipment tailored to their specific Kubota model.

Essential Tools for Maintenance

Essential tools for Kubota maintenance include wrenches, screwdrivers, pliers, and hammers. Diagnostic tools like multimeters and pressure gauges are crucial for troubleshooting. Specialized tools, such as torque wrenches and compression testers, are often required for specific tasks. Digital tools, including software for engine reprogramming, enhance maintenance efficiency. Operators should also keep a set of basic tools, like socket sets and Allen keys, readily available. Proper tool organization ensures quick access during repairs. Always refer to the Kubota manual for a detailed list of recommended tools tailored to your equipment model. Using the right tools ensures safety, accuracy, and prolongs machinery lifespan. Regularly inspect and maintain tools to prevent damage or malfunction during use;

Specialized Equipment for Repairs

Specialized equipment for Kubota repairs includes hydraulic pressure test kits, fuel injection testers, and engine compression gauges. These tools are designed to diagnose and address complex issues specific to Kubota machinery. Hydraulic test kits help identify leaks or pressure imbalances, while fuel injection testers ensure proper fuel delivery. Engine compression gauges are vital for assessing cylinder performance. Additionally, Kubota-specific diagnostic tools, such as the Kubota Diagnostic Tool (KDT), provide detailed insights into engine and system malfunctions. These advanced tools enable precise troubleshooting and efficient repairs, ensuring machinery operates at peak performance. Always use OEM-recommended equipment for reliability and accuracy.

Digital Tools and Software

Digital tools and software play a crucial role in enhancing the functionality of Kubota equipment. The Kubota Diagnostic Tool (KDT) enables real-time monitoring of engine performance, fault code analysis, and system calibration. Mobile apps like the myKubota app provide convenient access to manuals, maintenance schedules, and troubleshooting guides. Digital platforms also offer interactive parts catalogs, allowing users to identify and order components seamlessly. Additionally, software updates for Kubota systems ensure compatibility with the latest technologies. These tools streamline diagnostics, reduce downtime, and improve overall efficiency. Regular updates and proper training on these systems are essential for maximizing their benefits and maintaining optimal equipment performance. They are indispensable for modern Kubota operators aiming to stay ahead in agricultural and construction tasks.

Troubleshooting Common Issues

Troubleshooting common issues in Kubota equipment involves diagnosing engine performance, transmission, hydraulic, and electrical system problems using detailed manuals and diagnostic tools for effective resolution.

Engine Performance Problems

Engine performance issues in Kubota equipment often manifest as unexpected shutdowns, low power output, or unusual noises. These problems can stem from fuel system contamination, faulty injectors, or clogged air filters. Regular maintenance, as outlined in the manual, such as cleaning filters and checking fuel quality, can prevent these issues. If problems arise, the troubleshooting guide in the Kubota manual provides step-by-step diagnostics and repair procedures. Using specialized diagnostic tools, operators can identify faulty components and address them promptly. Early detection and resolution of engine issues are crucial to maintain productivity and extend equipment lifespan. Always refer to the manual for specific instructions tailored to your Kubota model for safe and effective troubleshooting.

Transmission and Hydraulic Issues

Transmission and hydraulic problems in Kubota equipment can lead to reduced functionality and operational delays. Common issues include fluid leaks, overheating, or unusual noises, often due to worn seals or contaminated fluids. The Kubota manual provides detailed diagnostic steps and repair procedures to address these problems. Regular fluid checks and filter replacements, as recommended, can prevent premature wear. Operators should consult the troubleshooting guide for specific instructions on identifying and resolving transmission and hydraulic faults. Proper maintenance and prompt repairs are essential to ensure smooth operation and maintain the longevity of Kubota machinery. Always adhere to the manual’s guidelines for safe and effective troubleshooting.

Electrical System Diagnostics

The Kubota manual provides detailed guidance for diagnosing electrical system issues, which are critical for equipment functionality. Common problems include blown fuses, faulty sensors, or malfunctioning solenoids. Operators should start by checking the fuse box and ensuring all connections are secure. Using a multimeter, as outlined in the manual, can help identify voltage drops or short circuits. Referencing the wiring diagrams in the manual is essential for tracing electrical pathways. Regular inspection of connectors and wires for corrosion or damage can prevent issues. Always follow the manual’s troubleshooting steps to isolate and resolve electrical faults efficiently, ensuring safe and reliable operation of Kubota equipment.

Best Practices for Manual Usage

Regularly review the manual to stay updated on procedures and safety guidelines. Update your knowledge with new manual versions for optimal equipment maintenance and performance.

Regular Review of Manual

Regularly reviewing the Kubota instruction manual ensures users stay informed about safety guidelines, operational procedures, and maintenance schedules. This practice helps prevent errors and enhances efficiency. Operators should revisit sections like safety precautions, troubleshooting, and maintenance intervals to stay updated. Checking for manual updates on official Kubota websites or through authorized dealers is crucial, as new information may be added. By familiarizing themselves with the manual, users can optimize equipment performance and extend its lifespan. Regular reviews also help identify potential issues early, reducing downtime and repair costs. Incorporating feedback from other users or professionals can further refine manual usage. Consistent review fosters a deeper understanding of the equipment, ensuring safe and effective operation.

Updating Manual Knowledge

Updating manual knowledge is vital for Kubota equipment users to stay informed about the latest revisions and enhancements. As Kubota regularly releases updated manuals, users should periodically check official Kubota websites or authorized dealers for new versions. This ensures access to the most accurate and detailed information, which is critical for safety, efficiency, and troubleshooting. Updated manuals often include new operational procedures, maintenance schedules, and technical specifications. By staying informed, users can optimize equipment performance and avoid potential issues. Regular updates also reflect advancements in technology and address common user concerns. Keeping manual knowledge current is a proactive approach to maximizing the lifespan and functionality of Kubota machinery. Consistent updates ensure users remain well-informed and equipped to handle evolving operational demands.

Using Manuals for DIY Repairs

Kubota instruction manuals are invaluable for DIY repairs, providing detailed step-by-step instructions and troubleshooting guides. They empower users to identify and resolve common issues independently, saving time and costs. Manuals include diagrams and parts lists, making it easier to locate and replace components. Before starting repairs, users should review safety precautions and ensure they have the necessary tools. For complex tasks, manuals often recommend seeking professional assistance. Regularly updating manual knowledge ensures access to the latest repair procedures and solutions. By following the manual’s guidance, DIY enthusiasts can perform repairs confidently, maintaining their equipment’s performance and longevity. Proper use of manuals enhances self-sufficiency and reduces reliance on external services. Always refer to the manual for specific instructions tailored to your Kubota model.

Additional Resources for Kubota Owners

Kubota owners can access online forums, official websites, and third-party libraries for manuals, troubleshooting guides, and DIY repair tips, enhancing their equipment maintenance and operation capabilities effectively.

Online Forums and Communities

Online forums and communities dedicated to Kubota equipment provide invaluable support for owners seeking advice, troubleshooting tips, and shared experiences. These platforms often feature discussions on maintenance, repairs, and optimal usage of Kubota machinery. Many forums include sections for downloading or accessing free manuals, service guides, and parts diagrams. For instance, communities like Kubota tractor forums or specialized groups on social media platforms allow users to connect with experienced operators and technicians. Additionally, these forums frequently share links to official Kubota resources, such as the Kubota.ca website, where operators can download specific manuals or guides. This collaborative environment fosters knowledge sharing and helps owners resolve issues efficiently, ensuring their equipment runs smoothly.

Workshop Manuals and Guides

Workshop manuals and guides for Kubota equipment are detailed resources designed to assist technicians and operators in performing advanced repairs and maintenance. These manuals typically include step-by-step instructions, diagrams, and specifications for various Kubota models, such as the Kubota V1903 and D950 engines. They cover procedures for disassembling and reassembling components, diagnosing issues, and replacing parts. Many workshop manuals are available for download from official Kubota websites or third-party libraries, ensuring easy access for those needing precise technical information. These guides are indispensable for ensuring that repairs are done correctly, maintaining the longevity and performance of Kubota machinery. They complement operator manuals by providing in-depth technical insights for more complex tasks.

Customer Support and Helplines

Kubota provides robust customer support and helplines to assist users with their equipment and manuals. Official Kubota websites offer direct access to support teams, ensuring prompt resolution of queries. Additionally, the myKubota app serves as a digital platform for accessing resources, including manuals and troubleshooting guides. Many Kubota owners also benefit from online forums and communities, where experienced users share knowledge and solutions. Customer support is available through various channels, including phone, email, and live chat, making it easy for users to seek help when needed. These resources enhance the overall ownership experience, ensuring that Kubota equipment is used effectively and efficiently.

The Kubota instruction manual is crucial for safe, efficient operation, and troubleshooting. Regularly reviewing it ensures optimal performance and extends equipment life effectively.

Final Thoughts on Manual Usage

The Kubota instruction manual is an indispensable resource for operators, offering detailed guidance for optimal equipment performance and longevity. By adhering to its instructions, users can ensure safety, efficiency, and proper maintenance. Regular reviews of the manual help operators stay updated on best practices and troubleshooting techniques. The availability of manuals on official Kubota websites and third-party libraries makes it accessible for all users. Leveraging digital tools like the myKubota app further enhances manual usage, providing a seamless experience. Whether for routine checks or complex repairs, the manual remains a cornerstone of responsible equipment ownership, empowering users to maximize their Kubota machinery’s potential effectively.

Encouragement for Proper Equipment Maintenance

Proper equipment maintenance is crucial for extending the life and performance of Kubota machinery. Regularly following the instruction manual ensures that all components function optimally, reducing wear and tear. By adhering to maintenance schedules, operators can prevent unexpected breakdowns and costly repairs. The manual provides clear guidelines on lubrication, filter replacements, and inspections, making it easier to maintain equipment proactively. Consistent upkeep not only enhances productivity but also supports safety and efficiency. Encouraging a routine maintenance culture ensures that Kubota equipment continues to deliver reliable service, meeting the demands of agricultural and construction tasks effectively. Proper care is an investment in both the machinery and its operational longevity.